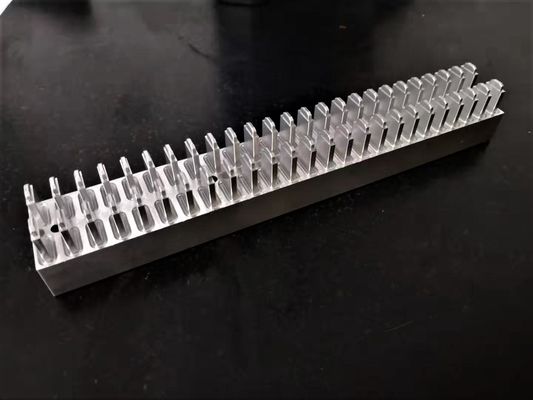

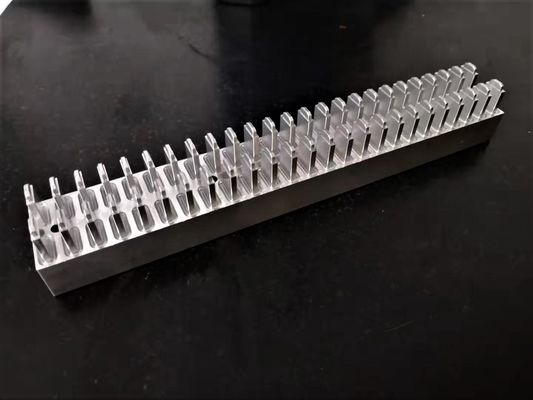

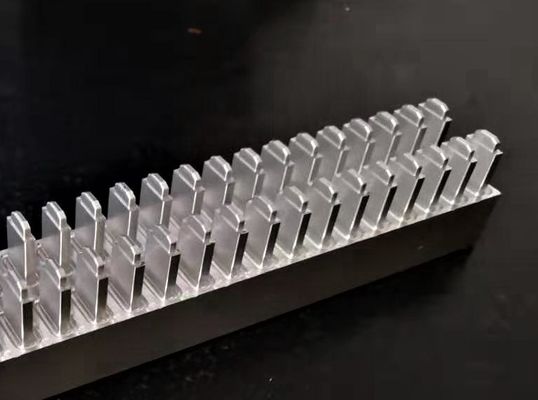

High Precision Machined Parts Vacuum Sucker Fixture Mechanical Arm Components

Customized Precision Machined Jig And Fixture Clamp Custom fixturing

Vacuum sucker fixtureMechanical arm parts Precision machined parts

Material: AL7075 Surface:Anodizing Concentricity:0.03mm

Rugosity:Ra0.8 Tolerance:0.01-0.03mm Diameter:Ø230mm

Flatness:0.03mm L*W*H(mm)=230mm*230mm*180mm

Metal:1.2344,SUJ2,45#,F125,F141,CK45,SKD11,DC53,SLD,S136,Q235,A5052,

SUS304,steel,Al,section bar, electrical device,etc..

machine:CNC processing center,CNC lathe,Wire cutting macine,Milling machine,

Grinding machine,EDM,wire cutting, Grinder,

Surface treatment:Ni plating, Anodizing,etc.

Purpose:Industrial using(Customization).Mobile phone assembly fixture,

Steaming fixture with optical lenses, Inspection fixture of Optical Communication Products,

Diamond Grinding fixture,Ceramic Products fixture,Electrical conduction inspection fixture,

Medical Wire Harness fixture,Aerospace Inspection and Correction fixture....

Why are you choose us ?

1) We have our own factories, quality can be controlled seriously.

2) We Specialize in manufacturing about10 years.

3) We have professional testing department and testing equipment.

4) We have 12 rich experience engineers & 20 senior technicians.

5) Timely delivery and excellent service.

6) We believe Reasonable price = High quality + Best service.

QC System:

1) Confirmed all drawings with customer and design the production way.

2) Checking the raw material before coming into our warehouse.

3) Confirmed the samples, reports of material and specs with customer.

4) Checking the process, machine, and other details in the production line.

5) Checking every products before packing them.

6) Checking the package before delivery.

FAQ:

Q1:Are you a manufacturer?

A1:Yes, we are a medium size ISO9001 certificated manufacturer with a wide range of advanced

equipment.Warmly welcome to visit our factory so that you can make sure this point.

Q2:What is the MOQ?

A2:Minimum Order Quantity is one piece/set.If you require more qty,the price can be more competitive.

Q3:Can you do the mass production?

A3:Yes,we are a factory which can provide service of precision CNC machining, rapid prototyping,

wire cutting, tooling building and etc.After you confirm the samples, we can start mass production.

It is very convienient for customers to

Choose us as a one-stop solution supplier.

Q4:Which 3D drawing files should go with the machines?

A4:CNC machines only read *IGS,*STP,*STEP,*IGES,*X-T format, for *STL format,it goes with

3D printer and SLA.

Q5:Is it possible to know how are my products going on without visiting your company?

A5:We will offer a detailed production schedule and send weekly reports with pictures or videos

which show the machining progress.

Q6:Will my drawings be safe after sending to you?

A6:Yes, we will keep them well and not release to third party without your permission.

Q7:What shall we do if we do not have drawings?

A7:Please send your sample to our factory,then we can copy or provide you better solutions.

Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be

made for you if placed order.

If you have any further questions, please just feel free to contact me directly. I will try my

best to service you and your company. I hope we will be a good cooperation in the futuue

Main Products Display

| Processing all kinds of metal and plastic matenrials with the change of the times,the materials chosen by customers are changing constantly,in order to meet the different material needs of customers,we have accumulated a very rich and wide range of process characteristics and technical know-how of mechanical processing of metal and non-metal materials through continuous technological innovation and research and development. |

| Steel |

Stainless steel |

Aluminum |

Copper |

Plastic |

Surface treatment |

| 1.2344 |

SUS303 |

A1050 |

C1020 |

PC |

High speed sand blasting |

| SUJ2 |

SUS304 |

A2017 |

C1100 |

PP |

Anodic oxidation |

| 1095 |

SUS316 |

A2024 |

C145 |

MC |

Nickel plating |

| 1212 |

SUS403 |

A5056 |

C147 |

POM |

Titanium plating |

| 1566 |

SUS416 |

A5052 |

C5191 |

ABS |

Gold plating |

| S355 |

SUS420J2 |

A6020 |

C1220 |

PVC |

Silver plating |

| C22 |

SUS430 |

A6061 |

C360 |

PEEK |

Chrome Plated |

| C45 |

SUS630 |

A6063 |

Others |

PMMA |

Blacking |

| F125 |

17-4PH |

A6082 |

|

Bakelite |

flame plating |

| F141 |

|

A7075 |

|

Teflon |

Abrasion |

| CK45 |

|

Others |

|

Others |

Chemical polishing |

| Others |

|

|

|

|

Others |

What technology services does XINYA provide?

Latest technology including:

CNC Milling Service

CNC Turning Service

CNC Milling and Turning Multiple

Mechanical Parts Design

Precision Engineering Services

Parts Assemble

EDM-Wire Cutting

Laser Cutting

Precision Grinding

Swiss Turning Machining

Auto-Lathing Turning

Injection Moulding

MIMMoulding Die Casting

Inverstment Casting…

Quality policy

With the rapid development of global economy, competition and challenges in various fields have

become inevitable. We are adhering to the firm spirit of enterprise and constantly pursue innovation,

and are brave enough to face and overcome all kinds of severe test.My team is consistently innovating

and developing our capability to align and meet the ever-changing market dynamics and technology

advancement, in providing efficient supply-chain &cost efficiency to our customers for their end—users.

we strongly believe in creating“win-win”synergy with our customers to build a long—term strategic

partnership for mutual growth.

Our measuring equipment:

CMM

Projector

Concentricity measurement

Hardness tester

Thread Ring Gauges

Pin Gauges

Micrometer

Vernier Caliper

Roughness machine

Our precision machined components are implemented of ISO9001:2015,combined with our in-house

quality control system and these measuring equipments,ensure problem-free products.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!